| 运行径向负载 (N.m) Operating radial load | 1764 |

| 运行轴向负载 (N.m) Operating axial load | 588 |

备注:径向负载为在轴伸1/2处

Radial load point is the 1/2 shaft output.

| 电机型号 Parameter | SM220 | |||||||||||||||

-47815 | -70015 | -95515 | ||||||||||||||

额定功率 | 7.5 | 11 | 15 | |||||||||||||

| 额定运行电压 Rated Voltage( 3Φ VAC) | 380 | 380 | 380 | |||||||||||||

额定电流 | 17 | 25 | 32 | |||||||||||||

额定转速 | 1500 | 1500 | 1500 | |||||||||||||

额定转矩 | 47.8 | 70 | 95.5 | |||||||||||||

峰值转矩 | 95.6 | 140 | 191 | |||||||||||||

反电势常数 | 170 | 170 | 180 | |||||||||||||

转矩常数 | 2.81 | 2.8 | 2.95 | |||||||||||||

转子惯量 | 186.2 | 271.6 | 338.8 | |||||||||||||

编码器线数 | 2500 | 2500 | 2500 | |||||||||||||

绝缘等级 | F | F | F | |||||||||||||

防护等级 | IP54 | IP54 | IP54 | |||||||||||||

使用环境要求 | 环境问题:0~+40°C 环境湿度:相对湿度<80% (无结霜) | |||||||||||||||

| 可选反馈元件 Optional feedback element | ·旋转编码器(Resolver) ·绝对值编码器17位或21位(Absolute encoder,17 bit or 21 bit) ·省线式光电编码器(9 wire encoder 2500PPR) | |||||||||||||||

绕组航插定义 | 管脚功能 Pin function | U | V | W | PE | |||||||||||

| 管脚编号 Pin Number | 2 | 3 | 4 | 1 | ||||||||||||

| 编码器航插定义 Signal Plugs definition | 管脚功能 Pin function | 5V | 0V | A+ | B+ | Z+ | A- | B- | Z- | U+ | V+ | W+ | U- | V- | W- | PE |

管脚编号 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 1 | |

航插规格 | 绕组插件型号:接线柱 编码器插件型号:YD28J15Z Power plugs model:connector bar Signal plugs model:YD28J15Z | |||||||||||||||

以上产品可按客户要求进行出轴规格、信号反馈元件类别、参数及相关配件定制。

Aboue Products can be customized according to customer requirement.

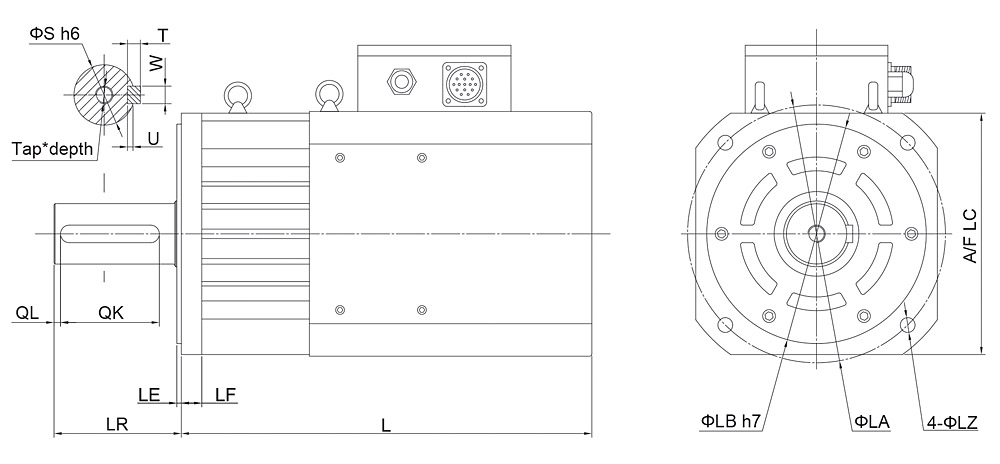

Model\Item | L | 外形尺寸(Outline drawing) | S | Tap*depth | 键(Key) | ||||||||||

LC | LR | LE | LF | LA | LB | LZ | QK | QL | W | T | U | ||||

SM200-47815 | 414 | 220 | 116 | 4 | 20 | 235 | 200 | 13.5 | 42 | M16*32 | 90 | 6 | 12 | 8 | 5 |

SM200-70015 | 464 | 220 | 116 | 4 | 20 | 235 | 200 | 13.5 | 42 | M16*32 | 90 | 6 | 12 | 8 | 5 |

SM200-95515 | 499 | 220 | 116 | 4 | 20 | 235 | 200 | 13.5 | 55 | M20*40 | 90 | 6 | 16 | 10 | 6 |

1. 安装或拆卸电机时,不得敲击电机及转轴,以免损坏编码器;

2. 尽量防止轴座的振动,以免损坏轴承;

3. 电机与驱动器须正确可靠连接,以免损坏电机和编码器;

4. 装配时,须确保电机轴和负载轴同心,以免损坏电机。

1.Never hit the servo motor or shaft,especially when coupling or disassembly theservo motor to machine,the encoder may become faulty.

2.Striving to make the best of its shaft to prevent vibration and bearing damage.

3.The motor and amolifier must be connected to be correct and reliable, so as not to damage motor and encoder.

4.When installing the motor, must ensure that the motor shaft and load shaft concentric, so as not to damage the motor and encoder.